Now I am making progress!

First up is the mast/keel box all nicely glassed in:

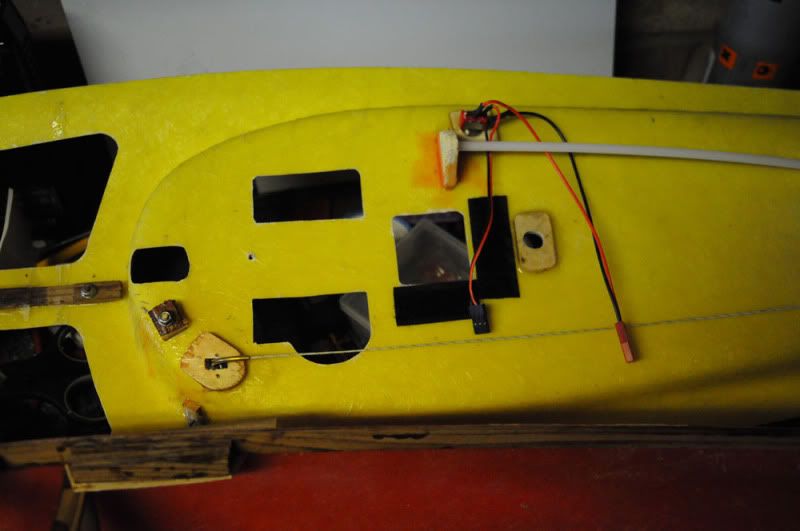

And the view forward showing the bulkheads. The king plank is bonded to the deck, enabling the track to be bolted on prior to fixing:

View of the front of the deck, the small piece of epoxyboard under the jib sheet guide is to stop the sheet getting caught

Here is the hull inverted for the rudder to be installed:

And this is a slightly off centre view, I reckon the rudder and keel line up pretty well perfectly.....:

This is the rudder bonded in the liteply circle weighs virtually nothing:

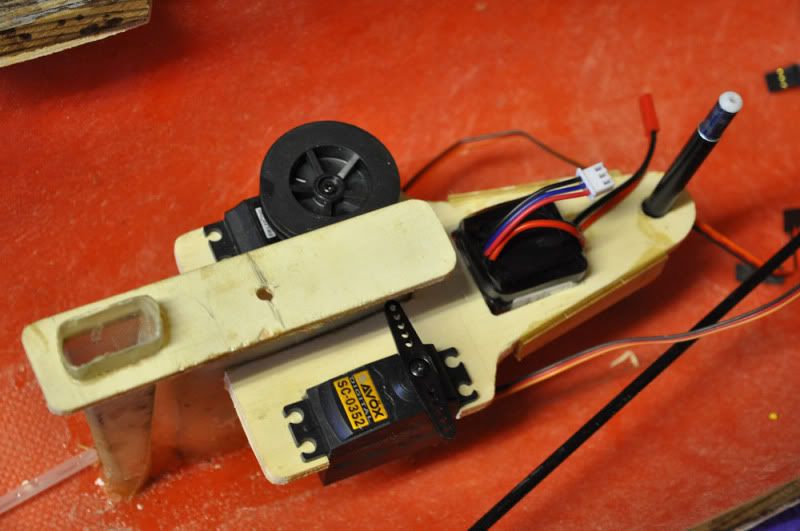

This is the start of the servo mounting plate made from 4mm ply, its currently 37grams which will reduce when I trim it down but it is very strong - probably a good thing!! Ebay is a good source of stainless m3 nuts and bolts at reasonable prices. Servos are an Eurgle 22 for the winch and a savox 352 for the rudder.

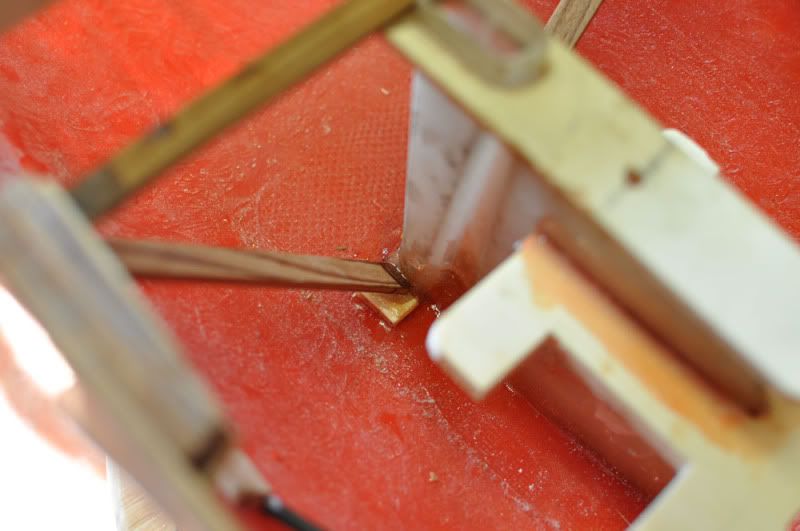

The carbon rod is wedged in place at below deck level to keep the hull in line. This will stay in place until the deck is bonded on then it will be removed via the servo holes.

This is the rear of the deck with the running rigging appearing from the through deck fitting and reversing around the pulley block: